<script type="text/javascript"> _linkedin_partner_id = "6415570"; window._linkedin_data_partner_ids = window._linkedin_data_partner_ids || []; window._linkedin_data_partner_ids.push(_linkedin_partner_id); </script><script type="text/javascript"> (function(l) { if (!l){window.lintrk = function(a,b){window.lintrk.q.push([a,b])}; window.lintrk.q=[]} var s = document.getElementsByTagName("script")[0]; var b = document.createElement("script"); b.type = "text/javascript";b.async = true; b.src = "https://snap.licdn.com/li.lms-analytics/insight.min.js"; s.parentNode.insertBefore(b, s);})(window.lintrk); </script> <noscript> <img height="1" width="1" style="display:none;" alt="" src="

×

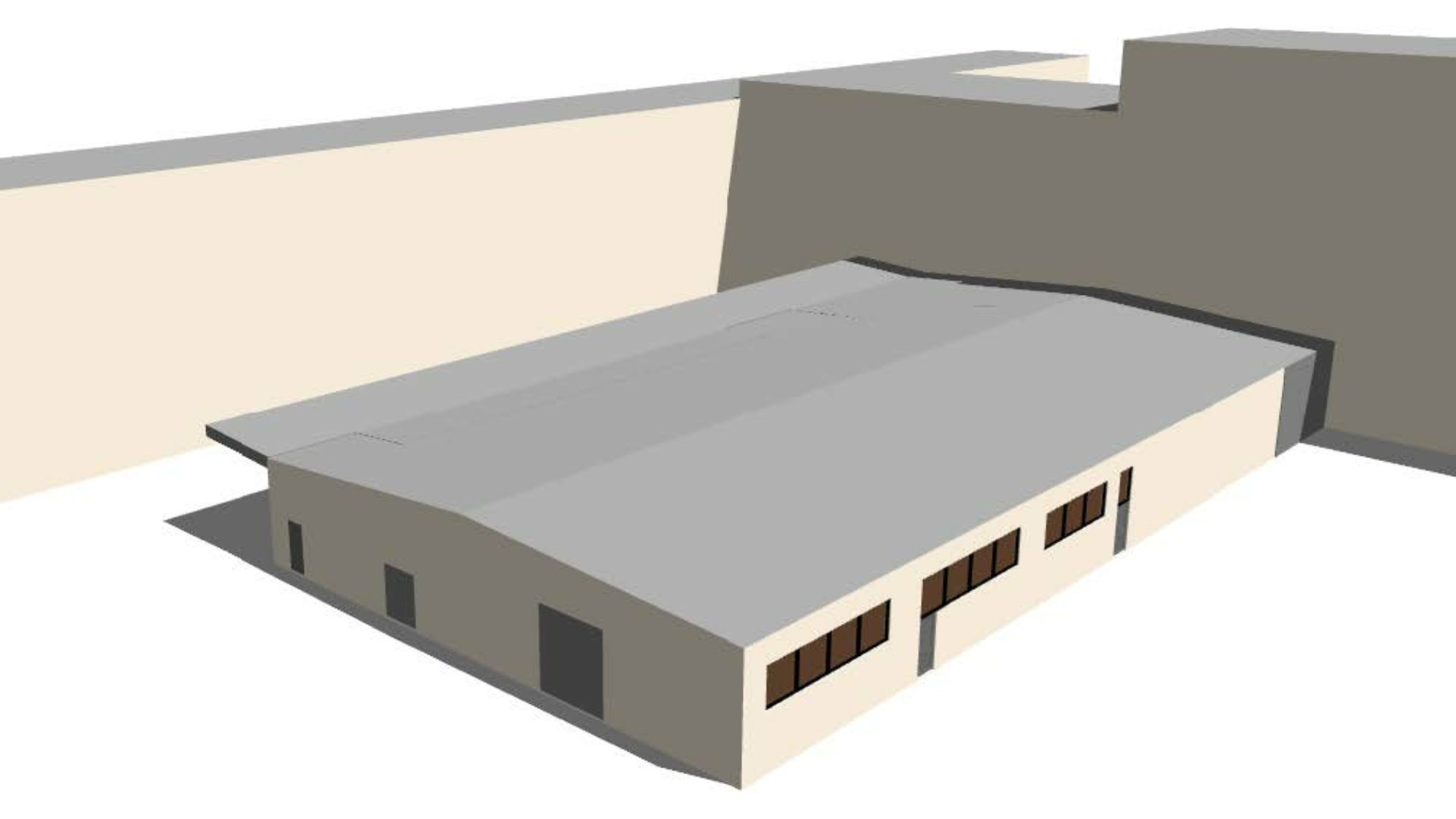

IN2 were appointed to design and oversee the mechanical and electrical service installations for the Baggage System upgrade and new build extension to the baggage hall at Shannon Airport.

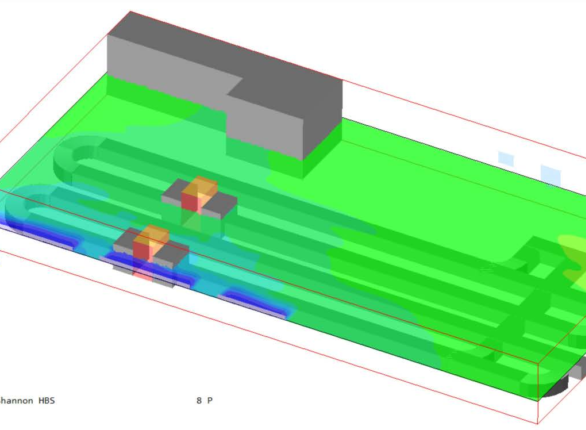

Overall the project comprises the design, supply, installation, testing, integration, validation, commissioning and certification of a Standard 3 Hold Baggage System (HBS) upgrade at the airport.

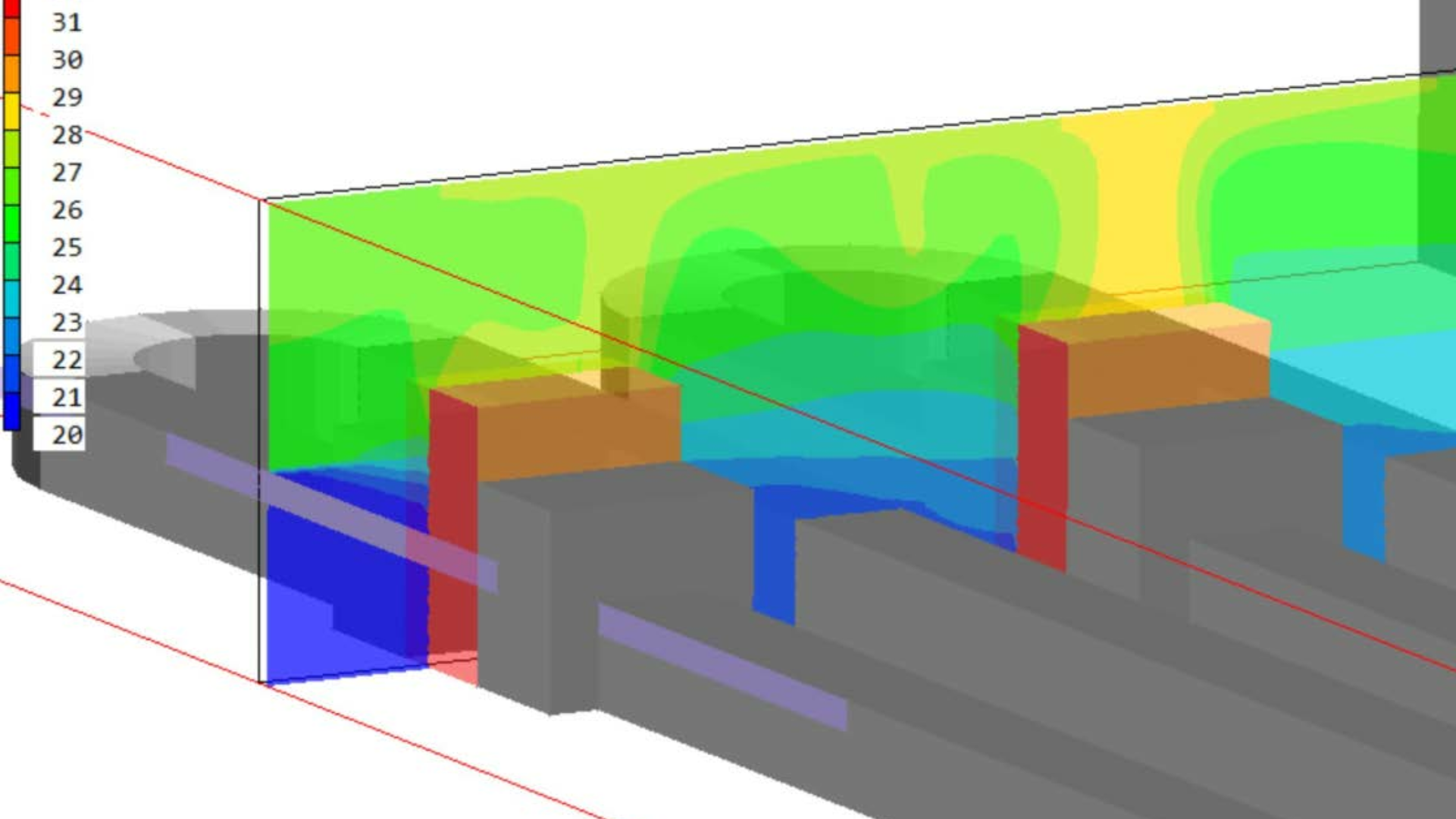

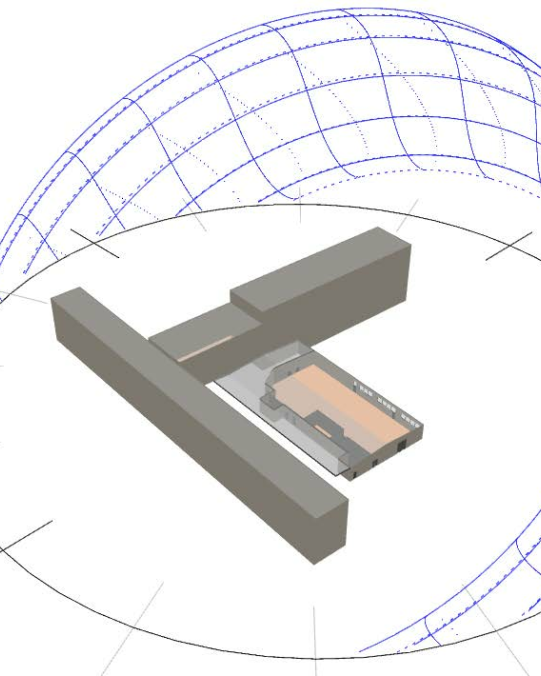

IN2 carried out environmental modelling and analysis to ensure daylighting and natural ventilation contributed to meeting and exceeding NZEB compliance for the new build extension to the baggage hall.

IN2 executed significant planning, coordination and phasing, minimising impact to the airport operations and security, and ensuring continuity of the airports regular operations.